What are six sigma resources?

The answer to the question “why is six sigma”, will give the answer to the question “what is six sigma resources?”

A defect free products or services are the foundation stone for the success of an organization or of a project. A defect free products and services are the result of high quality production of an organization. Six sigma is the methodology of the production of defect free, high quality products. Six sigma provides with the requirements for the production of quality products and to meet the customer satisfaction for the survival of the organization in the field of competitive global marketing. Implementation of six sigma helps the organization to focus on the improving quality of the products and services through better, faster and cheaper means. In a broad sense, it is easy to explain the use of six sigma as “the methodology focusing on defect prevention, cycle time reduction, and cost savings”. Six sigma helps in finding out the identifying and elimination of cost that provides no values to the customer satisfaction.

A defect free products or services are the foundation stone for the success of an organization or of a project. A defect free products and services are the result of high quality production of an organization. Six sigma is the methodology of the production of defect free, high quality products. Six sigma provides with the requirements for the production of quality products and to meet the customer satisfaction for the survival of the organization in the field of competitive global marketing. Implementation of six sigma helps the organization to focus on the improving quality of the products and services through better, faster and cheaper means. In a broad sense, it is easy to explain the use of six sigma as “the methodology focusing on defect prevention, cycle time reduction, and cost savings”. Six sigma helps in finding out the identifying and elimination of cost that provides no values to the customer satisfaction.

From the above description it is clear that six sigma is a systematical analyzing of measurement quality for the production of best quality products and the better customer satisfaction. Six sigma has a proven history of highly effective quality principles and techniques. The aim of six sigma is of virtually defect free business performances.

For the implementation of high quality products and the customer satisfaction, there are certain resources in six sigma methodology. Trainings, seminars, and certifications for the specific skills are their major resources. There are two methods in six sigma, DMAIC & DMADV.

The former is used to improve an existing business process, while the second one is used either for creating a new product or for process designs for predictable and defect free performance. By DMAIC, it means giving importance to defining, measuring, analyzing, improving and controlling a process to meet its better quality. The implementation of the six sigma methodology helps in providing a logical sequence for existing concepts and the problem solving tools, by sufficient repackaging of the tools and concepts. Moreover, the methodology of the six sigma is used by the project sponsors at each step of conclusion before moving to the next step.

Six sigma trainings:

Training the professionals about the methodologies of six sigma, which is a flexible system, is the aim of the six sigma training. This training provides the professionals and the companies with skills of achievement, supporting, and maximizing business profits. The training is based on the understanding the needs of the customer, systematical use of the data and the facts, improving and reinventing the organizational processes using statistical analysis. The training is designed in such a way that it provides the trainees a full resources to help them to explain, simplify and set the right path in the implementation of the six sigma methodology for the better achievement of the organization to meet its better quality.

Besides the above said basic trainings, six sigma provides training under two sections to make the training more effective and clear. The two sections are as follows:

Management training with certifications

Six sigma belt training with certifications

Under each section, there are several sub-divisions, according to the needs and the commitments of the company towards the customer. Each section is having its own importance for the attainment of the defect free results.

Six sigma seminars:

Six sigma seminars are instructional process, conducted for the candidates to know and discover how to apply systematically the statistical methods of six sigma for the organizational growth and for customer satisfaction. Instructions are given to the candidates about the importance and usage of data, information, analysis, and communication for a successful problem solving.

Six sigma seminars are instructional process, conducted for the candidates to know and discover how to apply systematically the statistical methods of six sigma for the organizational growth and for customer satisfaction. Instructions are given to the candidates about the importance and usage of data, information, analysis, and communication for a successful problem solving.

Six sigma seminars are conducted on the effective application of the six sigma theories and process, to make sure that the candidates are able to apply their knowledge effectively to assist the organizations to achieve the best in the global marketing. It also helps in reducing the costs, improving the time, eliminating the defects and improving the quality and the satisfaction of the customer.

Seminars are organized in such a way for the participant’s to use it friendly for the complete understanding of the methods used in six sigma. The participant’s are provided with training certificates after the completion of each seminar. The below mentioned topics are the different subjects offered for the six sigma seminars.

Measurement systems analysis

Process capability and performance

Advanced statistical methods

Design and analysis of experiments

Statistical process control and management

Six sigma certifications:

Six sigma certification give importance in giving training to the appropriate subject matter, through written proficiency test. This training provides with the displaying competency in the hands of the person. Six Sigma Certification has given by the training and consulting company, who is conducting the training. Even the companies hiring the training programs can give the tests. The tests may differ according to the training company’s proficiency. Companies performing training for years have created and administrated written proficiency tests of their own.

Once the certification training is completed, one must complete one or two quality projects. This is the time for the trainees to display the competency in applying the concepts learned. This part of the training differs according to the companies, and hence the quality projects are the fuzziest and the undefined part of the six sigma certification.

Under six sigma certification comes three types of certifications. They are:

Green belt certification

Black belt certification

Master black belt certification

Apart from this certification, there are yellow certification and lean certification. The word belt refers to the level six sigma projects to be performed. Business leaders processing six sigma through the projects are known as the champions. They are trained according to the six sigma methodology, which aims at the selection of the projects that are related with business goals. These champions are to select and monitor six sigma project leaders, who were called the “belts”. Six sigma certification requires both projects and training

CSSGB- Six Sigma Green Belt Certification

Here the six sigma green belt operators are given training to operate in the support or under the supervision of a six sigma black belt. Through this certification the person is trained to analyze and solve quality problems. This results in the quality improvement projects. The person, who had undergone the six sigma green belt certification, has at least three years of work experience in demonstrating the knowledge of six sigma tools and processes.

CSSBB- Six Sigma Black Belt Certification

The candidate who had undergone six sigma black belt certification is a professional who is capable in the explanation of six sigma philosophies and the principles. His knowledge also includes the supporting systems and the tools. This certification also deals with the training of the candidate in developing the demonstrating of the team leadership, understanding team dynamics and assigning team member roles and responsibilities. A six sigma black belt will be well versed will all the aspects of the DMAIC model in accordance with the six sigma principles. These professionals have basic knowledge of lean enterprise concepts. They are capable in identifying non-value added elements and activities. They are also capable in the use of specific tools

Master Black Belt Certification

The professionals who had undergone the master black belt certification are considered as a six sigma quality experts and they are responsible for the strategic implementations within an organization. The training is given for the improvement of the responsibilities of a master black belt, which includes training and mentoring of black belts and the green belts. Moreover the responsibilities or the duties of a master black belt extend to the range of helping the both belts in prioritizing, selecting and charting high impact projects.

Maintaining the integrity of the six sigma measurements, improvements and developing, revising six sigma training materials, qualifying or teaching the other six sigma facilitators about the methodologies, tools and applications in all functional areas of a company are some of the other responsibilities of a person who has completed master black belt certification.

Yellow Belt Certification

Six Sigma Yellow Belt certification provides with the attendees an overall insight to the use age of the six sigma techniques. The training is also given in the field of six sigma metrics and the basic improvement methodologies. It is essential for six sigma yellow belt to learn how to integrate lean and six sigma methodologies to get the high level production and transactional systems. This is to meet the customer’s expectations and the objectives of the organization from the bottom, to its best. The certification helps the trainees to receive an idea about the introduction to the process management and the basic tools of six sigma. Strong understanding of the processes, enabling each individual to provide meaningful assistance is the other characteristics of the six sigma yellow belt certification. The aim of this certification is the achievement of the organizations overall objectives.

Lean Six Sigma Certification

Lean six sigma certification provides the professionals with both techniques of service and manufacturing in industries. Along with this lean certification makes an individual attain the following requirements:

Lean six sigma certification provides the professionals with both techniques of service and manufacturing in industries. Along with this lean certification makes an individual attain the following requirements:

– Focusing how to move fast in order to accomplish the objectives with in the industry.

– Involves in business enterprise, identifies and eliminates the activities which do not provide values to the product or to the service given to the customer.

– Awareness of the lean and six sigma methodology help the business enterprise in attaining a stable improvement.

– The improvement will start from the bottom level and will be having a fast accomplishment

– Identifying the potential areas, deciding the improvements, meeting the customer expectation and the business results are other fields in which the trainees concentrate.

– Emphasis is given in chasing the variations and waste out of the system, so as to make sure that the improvements are sustained.

In an organization, the project sponsor seeks the help of six sigma methodology under several situations like:

When the cause of the low quality performance is unknown

When problems are found in common places

When the problems found are not able to well defined

When the approaches made are not inappropriate

When all the problem solving methods fail

When complex situations arises with many variables

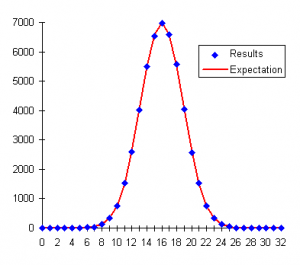

A Chi Square test also called as Chi-squared is a statistical hypothesis test that has a chi-square distribution when the null hypothesis is true. This test is most commonly used to observe what results are obtained by comparing given data with the expected data. This test is conducted to prove that there will be no change or difference between actual & expected data. The Chi-Square formula is sum of the squared difference between the actual & expected data, divided by the expected data.

A Chi Square test also called as Chi-squared is a statistical hypothesis test that has a chi-square distribution when the null hypothesis is true. This test is most commonly used to observe what results are obtained by comparing given data with the expected data. This test is conducted to prove that there will be no change or difference between actual & expected data. The Chi-Square formula is sum of the squared difference between the actual & expected data, divided by the expected data. India is a country where there are many companies who looks for the measure of goodness for their products and customer satisfaction. They always opt for a systematical and statistical improvement in the business world. Hence the implementation of the six sigma, for the effective operating system and to reduce the variation by avoiding defects and reducing waste is very much important for a country like India. Keeping this in mind, many companies in India opts the help and training of the six sigma methodologies, for the company professionals.

India is a country where there are many companies who looks for the measure of goodness for their products and customer satisfaction. They always opt for a systematical and statistical improvement in the business world. Hence the implementation of the six sigma, for the effective operating system and to reduce the variation by avoiding defects and reducing waste is very much important for a country like India. Keeping this in mind, many companies in India opts the help and training of the six sigma methodologies, for the company professionals. India gives importance to the DMAIC methodology in six sigma. The methodology of six sigma has two sub-divisions. They are DMAIC & DMADV. The former is used to improve an existing business process, while the second one is used either for creating a new product or for process designs for predictable and defect free performance. By DMAIC it means giving importance to defining, measuring, analyzing, improving and controlling a process to meet its better quality. The implementation of the six sigma methodology, helps in providing a logical sequence for existing concepts and the problem solving tools, by sufficient repackaging of the tools and concepts. Moreover the methodology of the six sigma is used by the project sponsors at each step of conclusion before moving to the next step.

India gives importance to the DMAIC methodology in six sigma. The methodology of six sigma has two sub-divisions. They are DMAIC & DMADV. The former is used to improve an existing business process, while the second one is used either for creating a new product or for process designs for predictable and defect free performance. By DMAIC it means giving importance to defining, measuring, analyzing, improving and controlling a process to meet its better quality. The implementation of the six sigma methodology, helps in providing a logical sequence for existing concepts and the problem solving tools, by sufficient repackaging of the tools and concepts. Moreover the methodology of the six sigma is used by the project sponsors at each step of conclusion before moving to the next step. Six sigma program offers an in-depth knowledge on the theories and applications of six sigma methodologies in specific business environment and organizations. The program focus on the systematical use of statistical methods in a scientific manner, for the purpose of solving critical problems with in an organization or the business. As far as, six sigma program is concerned, the program focus on the training of the statistical methods where in other training programs the attention is paid on the training of the functionality of software.

Six sigma program offers an in-depth knowledge on the theories and applications of six sigma methodologies in specific business environment and organizations. The program focus on the systematical use of statistical methods in a scientific manner, for the purpose of solving critical problems with in an organization or the business. As far as, six sigma program is concerned, the program focus on the training of the statistical methods where in other training programs the attention is paid on the training of the functionality of software. The professionals who had undergone the master black belt certification are considered as a six sigma quality experts and they are responsible for the strategic implementations within an organization. The training is given for the improvement of the responsibilities of a master black belt, which includes training and mentoring of black belts and the green belts. Moreover the responsibilities or the duties of a master black belt extend to the range of helping the both belts in prioritizing, selecting and charting high impact projects.

The professionals who had undergone the master black belt certification are considered as a six sigma quality experts and they are responsible for the strategic implementations within an organization. The training is given for the improvement of the responsibilities of a master black belt, which includes training and mentoring of black belts and the green belts. Moreover the responsibilities or the duties of a master black belt extend to the range of helping the both belts in prioritizing, selecting and charting high impact projects. Training the professionals about the methodologies of six sigma, which is a flexible system, is the aim of the six sigma training. This training provides the professionals and the companies with skills of achievement, supporting, and maximizing business profits. The training is based on the understanding the needs of the customer, systematical use of the data and the facts, improving and reinventing the organizational processes using statistical analysis. The training is designed in such a way that it provides the trainees a full resources to help them to explain, simplify and set the right path in the implementation of the six sigma methodology for the better achievement of the organization to meet its better quality.

Training the professionals about the methodologies of six sigma, which is a flexible system, is the aim of the six sigma training. This training provides the professionals and the companies with skills of achievement, supporting, and maximizing business profits. The training is based on the understanding the needs of the customer, systematical use of the data and the facts, improving and reinventing the organizational processes using statistical analysis. The training is designed in such a way that it provides the trainees a full resources to help them to explain, simplify and set the right path in the implementation of the six sigma methodology for the better achievement of the organization to meet its better quality. The head of the departments and above position personalities like the senior business executives are considered as the champions of the organization. They are the person, who is responsible in the selection of the right projects, finding out the project scope, assigning the project, pointing out the right person for the position of black belt, greenbelt, and as the team members. The responsibilities includes charting the project, finding and resolving the roadblocks for the progress of the project. In wide sense it is the overall responsibility of a champion for the success of the project. The champion is link between the top management and the project teams. Often the DMAIC process is followed

The head of the departments and above position personalities like the senior business executives are considered as the champions of the organization. They are the person, who is responsible in the selection of the right projects, finding out the project scope, assigning the project, pointing out the right person for the position of black belt, greenbelt, and as the team members. The responsibilities includes charting the project, finding and resolving the roadblocks for the progress of the project. In wide sense it is the overall responsibility of a champion for the success of the project. The champion is link between the top management and the project teams. Often the DMAIC process is followed The candidate who had undergone six sigma black belt certification is a professional who is capable in the explanation of six sigma philosophies and the principles. His knowledge also includes the supporting systems and the tools. This certification also deals with the training of the candidate in developing the demonstrating of the team leadership, understanding team dynamics and assigning team member roles and responsibilities. A six sigma black belt will be well versed will all the aspects of the DMAIC model in accordance with the six sigma principles. These professionals have basic knowledge of lean enterprise concepts. They are capable in identifying non-value added elements and activities. They are also capable in the use of specific tools

The candidate who had undergone six sigma black belt certification is a professional who is capable in the explanation of six sigma philosophies and the principles. His knowledge also includes the supporting systems and the tools. This certification also deals with the training of the candidate in developing the demonstrating of the team leadership, understanding team dynamics and assigning team member roles and responsibilities. A six sigma black belt will be well versed will all the aspects of the DMAIC model in accordance with the six sigma principles. These professionals have basic knowledge of lean enterprise concepts. They are capable in identifying non-value added elements and activities. They are also capable in the use of specific tools The curriculum of six sigma training in UK is lined with the “American society for quality” which is endorsed by the “European organization for quality”. In UK, the training is done through the direct entry of all programs except in the case of master black belt training program. In the case of master black belt training, six sigma black belt training with a reputed training provider is a prerequisite.

The curriculum of six sigma training in UK is lined with the “American society for quality” which is endorsed by the “European organization for quality”. In UK, the training is done through the direct entry of all programs except in the case of master black belt training program. In the case of master black belt training, six sigma black belt training with a reputed training provider is a prerequisite. “Six sigma champion training and certification

“Six sigma champion training and certification